Details;

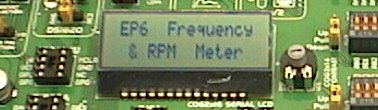

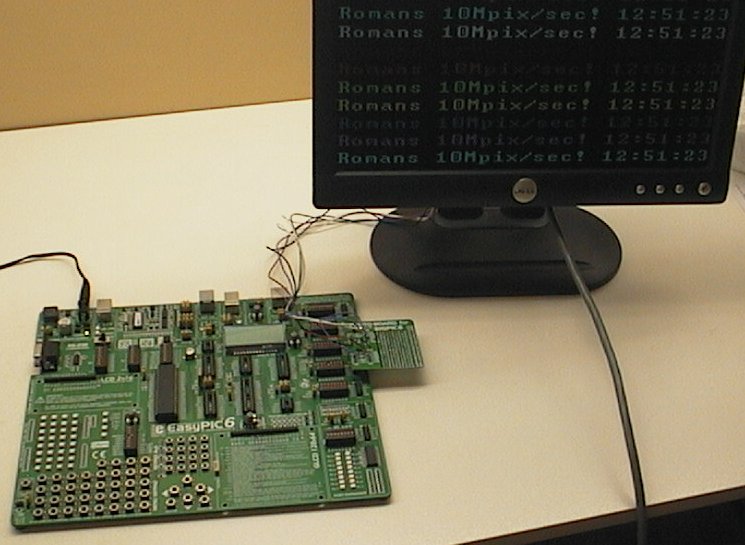

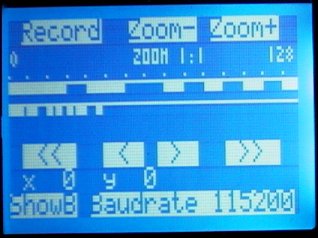

I just used the COG LCD display example that came with the MikroC PRO compiler for the COG display driving. This is very easy to use. The frequency meter code is my own, I just setup the 2 timers, and did some calculating and formatting code so Freq and RPM can both be displayed.

Special hardware...

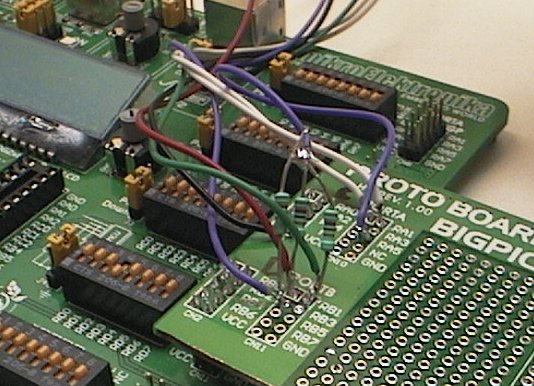

I used a 555 timer oscillator connected to PORTC.F0. This is just a tiny PCB with a 555 timer and a pot to adjust the speed. This mimics the signal from an "engine" or machine etc so the project can display RPM. You don't need this, you can just press the RC0 button real fast!

Adapting this code;

I used the EasyPIC6 COG display because I was testing the new EasyPIC6 develoment board and the COG was the thing I wanted to test. However my simple source code will work fine with any normal text LCD. All you need to do to adapt it to your normal LCD is to setup your LCD as usual, and then change these LCD function names from;

SPI_Lcd_Out(1,14,"Hz");

to;

Lcd_Out(1,14,"Hz");

This .ZIP file contains the MikroC PRO source code in C, the project file, the autogenerated assembler .LST file;

EP6_FREQ.zip

EasyPIC6 Project 2. Accurate PWM signal generator - 12th Oct 2009.

What is it?

This project uses the built in PWM module in the PIC 16F887 (or 16F877). It generates an output signal with the PWM (pulse width modulation) adjustable over the entire 10bit range from 0 to 1023 (full).

It can be used for driving DC motors to control their speed, or controlling lights (including LED lights) to control their brightness etc.

Controls;